- Company Profile

- Company Video

- Corporate History

- Environmental Responsibility

- Innovators in Plastic

- Home

- About Us

- Company Profile

Company Profile

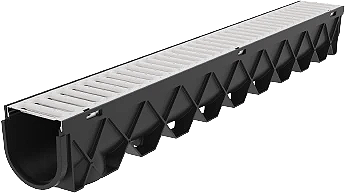

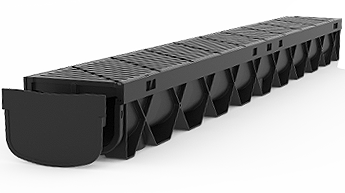

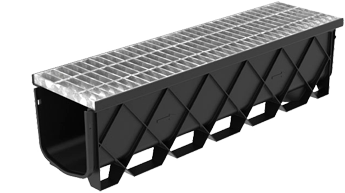

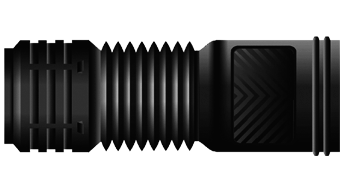

Reln is a multi-award winning and quality-endorsed Australian company, known for designing and producing innovative quality plastic products for the Australian and international markets.Widely acclaimed in both industry and environmental forums, Reln manufactures its own lines of domestic and industrial products with applications as diverse as surface water drainage, plumbing, agriculture, aquaculture and gardening.

Reln also provides design and product management for leading manufacturers in the packaging, automotive, medical, electronic goods and consumer industries. Reln is at the vanguard of the development of large injection mouldings in Australia. Our large modern plant in southwestern Sydney houses state-of-the-art injection-moulding machinery complimented with other technologies including extrusion, rotational moulding, painting and other product decoration techniques. Reln is capable of manufacturing mouldings ranging from 10 grams to 120 kilograms according to any customer requirements.

Our Team

Jenilee Goncalves | Customer Service Manager

Most recently serving as Store Manager for a big box national retailer, Jenilee brings over 19 years experience in customer service to the role. She aims to provide an excellent customer experience and oversees day to day operations at the office. In her down time, Jenilee enjoys travelling, reading, and spending time with her young daughter.

Lucy Limanni-Joseph | Accounts Manager

With over 15 years of experience in accounting and finance, Lucy is well versed in accounts receivable, accounts payable, collections, and business analytics. For Lucy, integrity is key, and she takes pride in a job well done. She enjoys the outdoors, photography, and spending quality time with her daughter and husband.

Butch Sauco | Warehouse Manager

Having more than 10 years of experience in shipping across various platforms & extremely familiar with the use of different software tools, Butch oversee the Canadian warehouse operations. Father of four children, Butch enjoys spending quality family time.

Mark Rego | Sales Manager

Dedicated, hard-working and passionate about his job, Mark ensures that customer satisfaction is of utmost importance, by developing a good rapport and relations with all customers. When Mark is not working, he is entertaining and hosting all his family and friends for a great gathering.

Ken Kong | Procurement Manager

With his extensive experience in the manufacturing and distribution industry, Ken oversees stock and production management across North America, as well as global production plants. Ken loves to travel and enjoys great food.

Jim Suriano | Vice President Sales & Marketing

With more than 25 years selling experience in the Hardware retail sector & 5 years within the trade industry, Jim enjoys and understands the ever-changing consumer purchasing demands. Outside of work, Jim loves spending family time with his 3 girls and wife.

- Home

- About Us

- Company Video

Company Video

- Home

- About Us

- Corporate History

Corporate History

Reln Pty. Ltd. was established in Victoria, Australia in 1955. The company’s first products focused on the dispersal of effluent water. Reln led the way in gaining public recognition and Government health department approval for their new approach.In 1970 Reln converted its production methods to polypropylene injection moulding, commissioning what was at the time the largest plastic injection-moulding die in Australia.

In the 1980s Reln began a period of intense research and development designed to expand the application of injection-moulded plastic in domestic and industry use. Under a grant from the Australian Research and Development Board, Reln designed and built the SP-1 Structural Foam Injection-Moulding Machine, which introduced a new concept of injection-moulding to Australia. Reln applied the new technology to the manufacture of robust one-piece large-capacity plastic containers that made an immediate impact on traditional methods used in waste water management, agriculture, and aquaculture.

The 1990s saw a dramatic expansion in Reln’s market presence in Australia and overseas. The development and manufacture of 2,450 litre containers, a world first for Australia and the first of Reln’s overseas exports, was accompanied by the development of other innovative products that significantly improved waste-water management by communities and households not connected to city-operated services.

Reln diversified its operations by entering the agricultural market, adapting its technology to develop a line of large-scale robust storage and animal-feeding products that now dominate the Australian market.

Reln also began to forge strong relationships with the environmental movement. The company began developing a revolutionary waste-minimisation and recycling technology incorporating the then-relatively obscure science of vermiculture. In just a few years Reln’s Worm Factory and Can-O-Worms have achieved a world-wide profile.

With the 1995 opening of new expanded premises at Ingleburn in Sydney’s southwest, Reln introduced further proprietary product lines, including an award-winning surface water drainage system. Reln also significantly increased its outreach to the corporate sector and designed and developed state-of-the-art products for a broad range of industries including packaging automotive, medical, electronic products and consumer goods.

- Home

- About Us

- Environmental Responsibility

Environmental Responsibility

Environmental responsibility has been one of the cornerstones of Reln’s development. All Reln’s proprietary range of products are made mostly from polypropylene or polyethylene. Of all the polymers used by the plastics industry, polypropylene and polyethylene have the most viable second-life application and are the most easily sourced from the waste stream.Reln pioneered the use of recycled plastic in Australia and is now one of its leading consumers. Unless required by a product’s unique specifications, Reln routinely uses recycled plastic in its products. Reln’s program development team emphasises environmentally responsible solutions to meet its corporate client’s needs.

Reln’s contributions to waste-minimisation and recycling have garnered significant recognition and numerous awards. Reln has developed strong corporate relationships with leading environmental organisations such as Landcare Australia, Keep Australia Beautiful, and the Environmental Protection Agency, as well as Government health departments and local governments. Reln’s line of recycling products are now distributed by more than 350 local governments in Australia.

- Home

- About Us

- Innovators in Plastic

Innovators in Plastic

Reln’s growing corporate client base includes leading manufacturers in packaging, automotive, medical, electronic products and consumer goods. Reln’s team of skilled designers and program development specialists are always ready to provide innovative, custom-fit solutions to meet the most exacting needs of its corporate clients.Whether the project be development of x-ray translucent patient rescue boards, specialised materials handling, complete air-conditioning units, or our own product lines, Reln’s development team involves all interested departments within the client organisation to achieve the desired final result.

With over 40 years’ experience, Reln has made a significant contribution to plastics technology, developed a range of innovative award-winning products, and established an enviable reputation for innovative solutions for its growing corporate clientele. Reln is a leading player in the Australian plastics industry and is set to play a similar role overseas.

- Company Profile

- Company Video

- Corporate History

- Environmental Responsibility

- Innovators in Plastic

- Home

- About Us

- Company Profile

Company Profile

Reln is a multi-award winning and quality-endorsed Australian company, known for designing and producing innovative quality plastic products for the Australian and international markets.Widely acclaimed in both industry and environmental forums, Reln manufactures its own lines of domestic and industrial products with applications as diverse as surface water drainage, plumbing, agriculture, aquaculture and gardening.

Reln also provides design and product management for leading manufacturers in the packaging, automotive, medical, electronic goods and consumer industries. Reln is at the vanguard of the development of large injection mouldings in Australia. Our large modern plant in southwestern Sydney houses state-of-the-art injection-moulding machinery complimented with other technologies including extrusion, rotational moulding, painting and other product decoration techniques. Reln is capable of manufacturing mouldings ranging from 10 grams to 120 kilograms according to any customer requirements.

Our Team

Jenilee Goncalves | Customer Service Manager

Most recently serving as Store Manager for a big box national retailer, Jenilee brings over 19 years experience in customer service to the role. She aims to provide an excellent customer experience and oversees day to day operations at the office. In her down time, Jenilee enjoys travelling, reading, and spending time with her young daughter.

Lucy Limanni-Joseph | Accounts Manager

With over 15 years of experience in accounting and finance, Lucy is well versed in accounts receivable, accounts payable, collections, and business analytics. For Lucy, integrity is key, and she takes pride in a job well done. She enjoys the outdoors, photography, and spending quality time with her daughter and husband.

Butch Sauco | Warehouse Manager

Having more than 10 years of experience in shipping across various platforms & extremely familiar with the use of different software tools, Butch oversee the Canadian warehouse operations. Father of four children, Butch enjoys spending quality family time.

Mark Rego | Sales Manager

Dedicated, hard-working and passionate about his job, Mark ensures that customer satisfaction is of utmost importance, by developing a good rapport and relations with all customers. When Mark is not working, he is entertaining and hosting all his family and friends for a great gathering.

Ken Kong | Procurement Manager

With his extensive experience in the manufacturing and distribution industry, Ken oversees stock and production management across North America, as well as global production plants. Ken loves to travel and enjoys great food.

Jim Suriano | Vice President Sales & Marketing

With more than 25 years selling experience in the Hardware retail sector & 5 years within the trade industry, Jim enjoys and understands the ever-changing consumer purchasing demands. Outside of work, Jim loves spending family time with his 3 girls and wife.

- Home

- About Us

- Company Video

Company Video

- Home

- About Us

- Corporate History

Corporate History

Reln Pty. Ltd. was established in Victoria, Australia in 1955. The company’s first products focused on the dispersal of effluent water. Reln led the way in gaining public recognition and Government health department approval for their new approach.In 1970 Reln converted its production methods to polypropylene injection moulding, commissioning what was at the time the largest plastic injection-moulding die in Australia.

In the 1980s Reln began a period of intense research and development designed to expand the application of injection-moulded plastic in domestic and industry use. Under a grant from the Australian Research and Development Board, Reln designed and built the SP-1 Structural Foam Injection-Moulding Machine, which introduced a new concept of injection-moulding to Australia. Reln applied the new technology to the manufacture of robust one-piece large-capacity plastic containers that made an immediate impact on traditional methods used in waste water management, agriculture, and aquaculture.

The 1990s saw a dramatic expansion in Reln’s market presence in Australia and overseas. The development and manufacture of 2,450 litre containers, a world first for Australia and the first of Reln’s overseas exports, was accompanied by the development of other innovative products that significantly improved waste-water management by communities and households not connected to city-operated services.

Reln diversified its operations by entering the agricultural market, adapting its technology to develop a line of large-scale robust storage and animal-feeding products that now dominate the Australian market.

Reln also began to forge strong relationships with the environmental movement. The company began developing a revolutionary waste-minimisation and recycling technology incorporating the then-relatively obscure science of vermiculture. In just a few years Reln’s Worm Factory and Can-O-Worms have achieved a world-wide profile.

With the 1995 opening of new expanded premises at Ingleburn in Sydney’s southwest, Reln introduced further proprietary product lines, including an award-winning surface water drainage system. Reln also significantly increased its outreach to the corporate sector and designed and developed state-of-the-art products for a broad range of industries including packaging automotive, medical, electronic products and consumer goods.

- Home

- About Us

- Environmental Responsibility

Environmental Responsibility

Environmental responsibility has been one of the cornerstones of Reln’s development. All Reln’s proprietary range of products are made mostly from polypropylene or polyethylene. Of all the polymers used by the plastics industry, polypropylene and polyethylene have the most viable second-life application and are the most easily sourced from the waste stream.Reln pioneered the use of recycled plastic in Australia and is now one of its leading consumers. Unless required by a product’s unique specifications, Reln routinely uses recycled plastic in its products. Reln’s program development team emphasises environmentally responsible solutions to meet its corporate client’s needs.

Reln’s contributions to waste-minimisation and recycling have garnered significant recognition and numerous awards. Reln has developed strong corporate relationships with leading environmental organisations such as Landcare Australia, Keep Australia Beautiful, and the Environmental Protection Agency, as well as Government health departments and local governments. Reln’s line of recycling products are now distributed by more than 350 local governments in Australia.

- Home

- About Us

- Innovators in Plastic

Innovators in Plastic

Reln’s growing corporate client base includes leading manufacturers in packaging, automotive, medical, electronic products and consumer goods. Reln’s team of skilled designers and program development specialists are always ready to provide innovative, custom-fit solutions to meet the most exacting needs of its corporate clients.Whether the project be development of x-ray translucent patient rescue boards, specialised materials handling, complete air-conditioning units, or our own product lines, Reln’s development team involves all interested departments within the client organisation to achieve the desired final result.

With over 40 years’ experience, Reln has made a significant contribution to plastics technology, developed a range of innovative award-winning products, and established an enviable reputation for innovative solutions for its growing corporate clientele. Reln is a leading player in the Australian plastics industry and is set to play a similar role overseas.

TALK TO SALES

Interested with our products?

Give us a call and chat with a member of our sales team

CONTACT CUSTOMER SUPPORT

Sometimes you need a little help, don’t worry we are here for you.

Contact Support